Product inspection equipment for quality control and contamination detection processes.

Products.

WEIGHT CONTROLLERS

Checkweigher systems offer profitable and productive solutions for the food, beverage, pharmaceutical, chemical and cosmetic industries. Currently, quality assurance in production operations is not conceivable without modern checkweighers.

SAFELINE SYSTEM METAL DETECTORS

Safeline metal detectors for food processing can inspect products in all formats, from food products packed on conveyor belts and raw powders or granular materials to liquids, pastes and food fluids.

Safeline Pharmaceutical Metal Detectors provide stand-alone inspection systems for use with all types of tablets, capsules, and powdered pharmaceuticals. These systems guarantee compliance with regulatory requirements, as well as the validation and qualification of procedures.

SAFELINE X-RAY PRODUCT INSPECTION

Safeline X-ray product inspection solutions improve product safety and quality control. Advanced systems are capable of detecting physical contaminants in products while performing a wide range of online quality control checks.

Safeline X-ray is a leading provider of contamination detection and quality control inspection equipment. Food, beverage and pharmaceutical manufacturers around the world rely on our online x-ray inspection systems on a daily basis to protect the well-being of consumers, preserve brand reputations, minimize the risk of costly operations. product recalls and contribute to regulatory compliance.

MANAGEMENT SOFWARE FOR PRODUCT INSPECTION

Software Perfect integration of product inspection devices. No matter what role you play in product inspection management, you will face many challenges in markets that are increasingly demanding more and contributing less.

ProdX Inspect data management software enables seamless integration of product inspection devices, further streamlining processes and making them more accessible and efficient. ProdX allows you to control the entire product inspection management process from a single point or from remote locations, eliminating the need for time-consuming production line checks.

Downloads.

Do you have any request?

- Servicinig

- Spare parts

- Quotes

- rrodriguez@mapersa.com +57 312 306 3363

- rbuenahora@mapersa.com +57 322 670 9690

- asistente.mettler@mapersa.com +57 321 642 6648

Inspect, detect and protect. Inspection systems for empty and full bottles and boxes.

Equipment

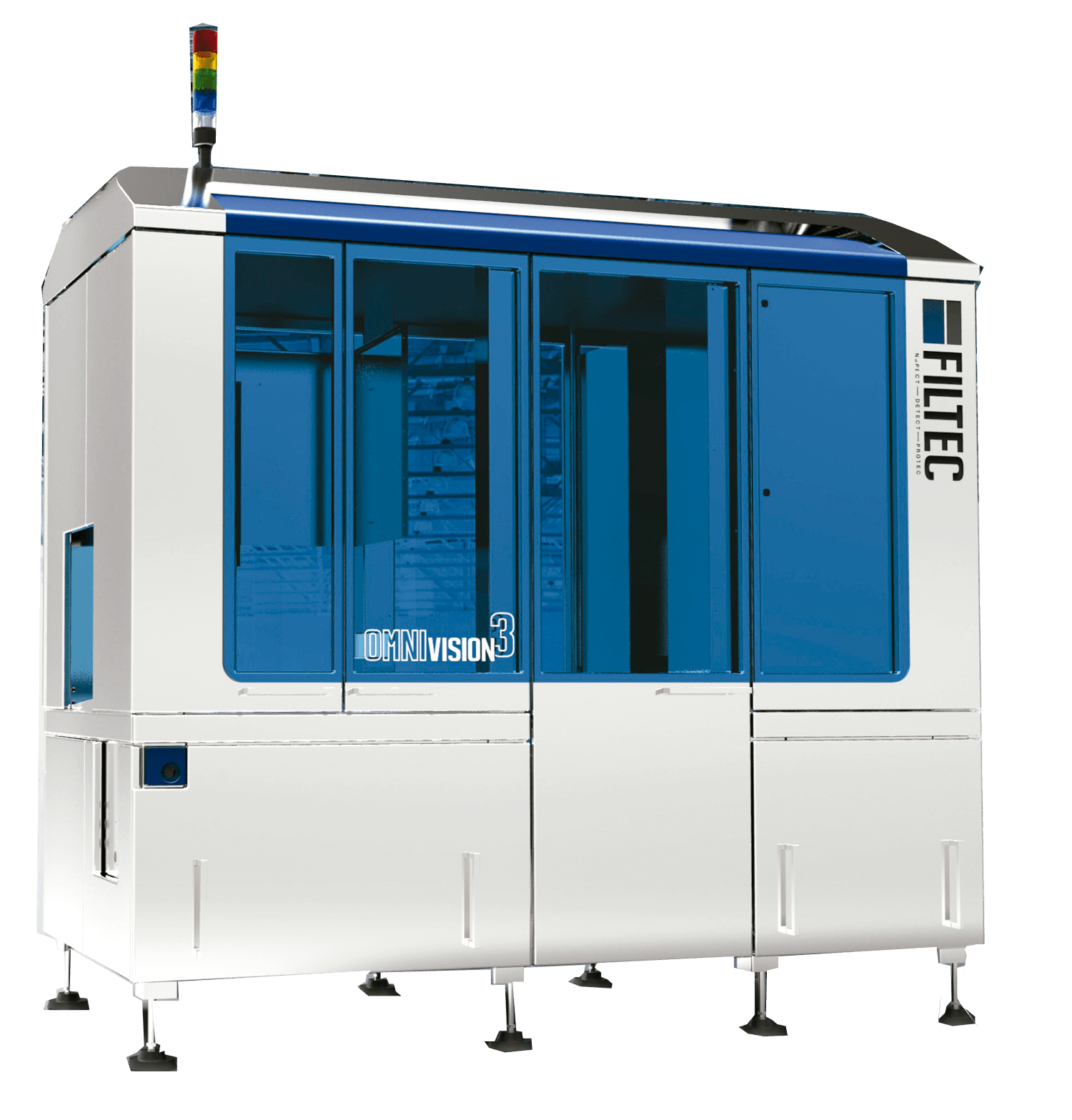

OMNIVISION III (GLASS-PET)

The Omnivision III is a full-surface PET and empty bottle inspection system that detects foreign objects and defects in the base, side wall, finish and threads of empty clear containers. It has the fastest image processing technology on the market.

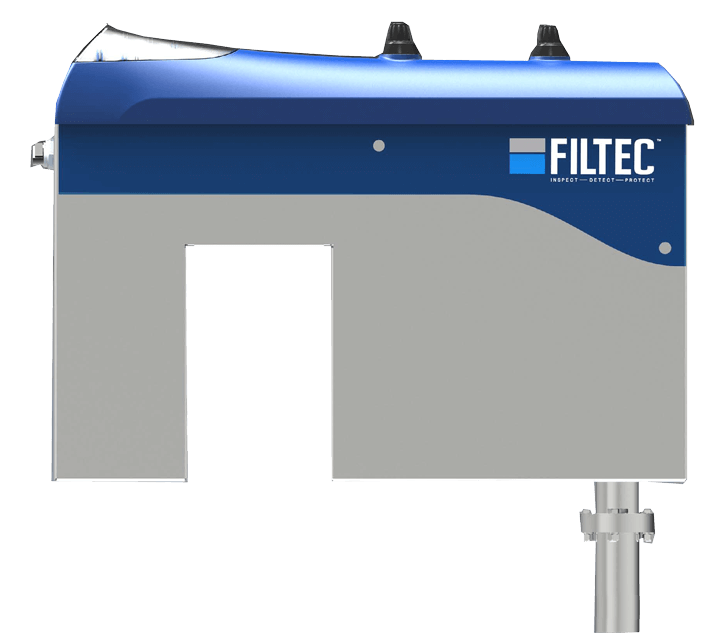

LEVEL INSPECTORS - full containers

Detects low-level or high-fill containers and lid closure defects at a rate of up to 2,400 containers per minute.

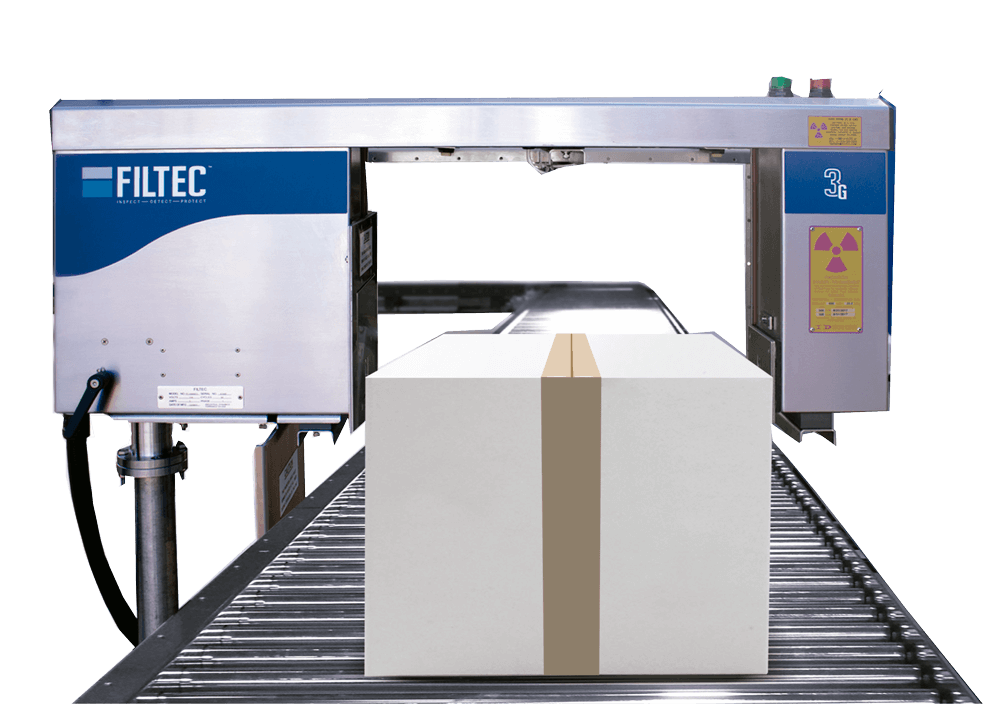

CRATE INSPECTORS

Full inspection for closed or open boxes with glass, PET or can containers.

FILL VALVE MONITORING

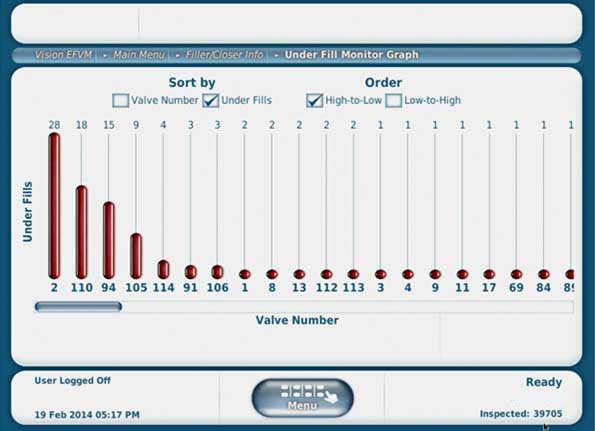

Closely monitoring of filler and capper operation keeps high-speed line operations smooth. FILTEC systems can identify non-working valves and capper heads in seconds. Immediate warnings prevent wasted product, container damage, and line failure. The analysis provides detailed fundamentals for line planning and optimization.

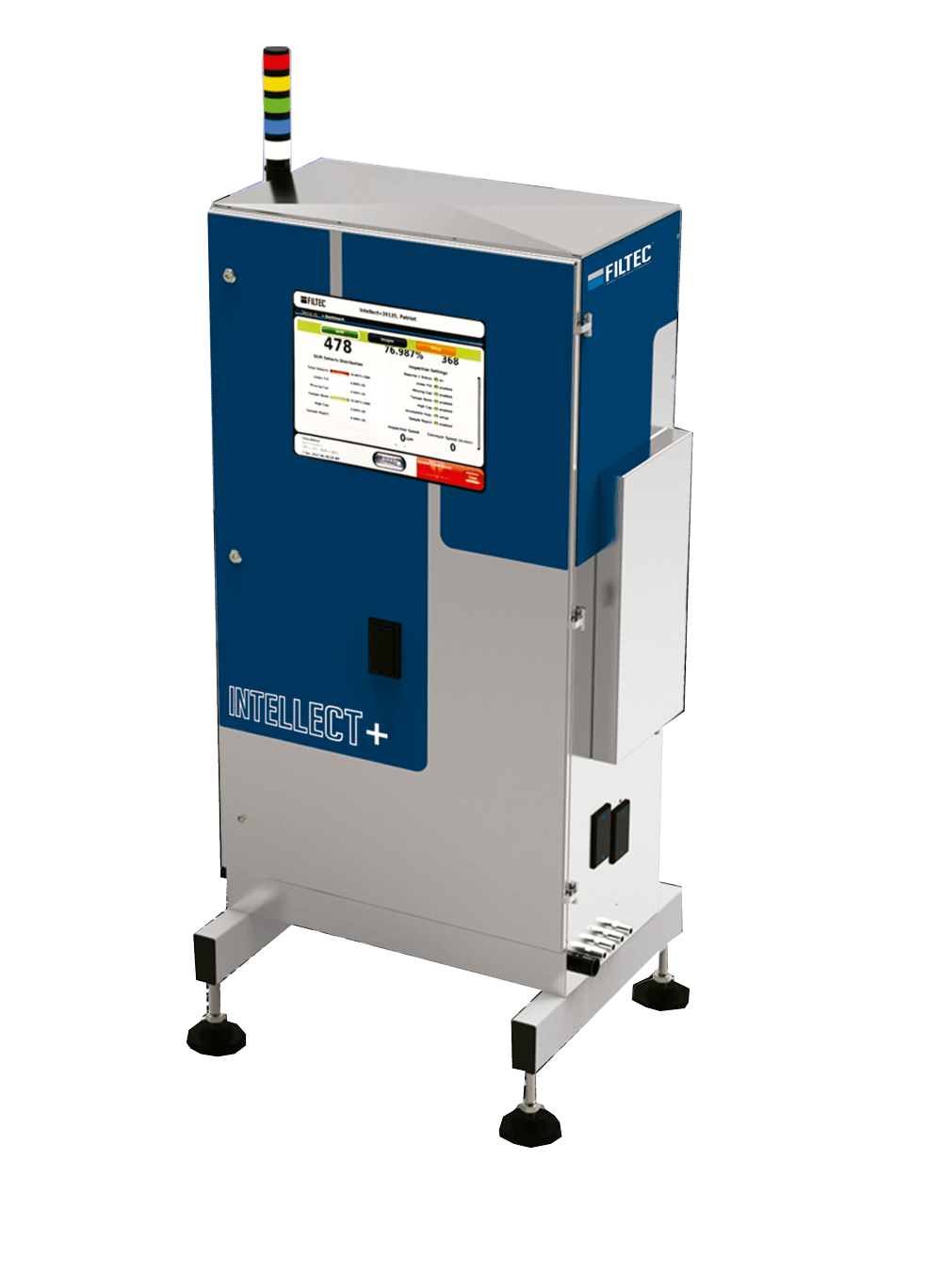

INTELECT PLUS

Modular system interface easily adaptable to current and future FILTEC equipment, systems and applications. FILTEC has focused all efforts on ensuring upgradeability to meet the most challenging customer needs.

Download

Do you have any request?

- Technical service

- tfiltec@mapersa.com +57 321 780 9295

- Spare parts and equipment quotes

- lalvarez@mapersa.com