DataFlex 6530 and 6330 Thermal Transfer Encoders

With iAssureTM built-in code quality assurance technology, low wear parts, electronic self-setting design, and quick-change tape cassette, the 6530 and 6330 offer the advantage of longer uptime .

DataFlex® 6330 is a medium speed thermal transfer printer that can help improve uptime and offer more productive operation, helping to reduce time spent on quality checks, rejects, and reruns.

In addition to the features available on the 6330, the 6530 high-speed thermal transfer printer offers print speeds of up to 1000mm / s and outputs of up to 700ppm *.

* Depending on application and substrates. IAssureTM technology is not currently supported for use in high-speed, high-performance, or ribbon-saving print modes.

| Specification | * 6530 | ** 6330 |

|---|---|---|

| Encoder mode | Intermittent and continuous movement | Intermittent and continuous movement |

| Gap between prints | 0.5mm | 0.5mm |

| Belt widths | 20mm (0.8 ") and 55mm (2.2") max. | 20mm (0.8 ") and 55mm (2.2") max. |

| Continuous mode: | ||

| Maximum printing area (width x length) | 53mm (2.1 ”) wide x 300mm (11.8”) long | 53mm (2.1 ”) wide x 200mm (7.9”) long |

| Maximum print speed | 1000 mm / s (39.4 in / s) | 750 mm / s (29.5 in / s) |

| Intermittent mode: | 800 mm / s (31.5 in / s) | - |

| Minimum print speed | Intermittent mode: 10 mm / s (0.4 in / s) Continuous mode: 1 mm / s (0.04 in / s) |

Intermittent mode: 40 mm / s (1.6 in / s) at full print quality; 10 mm / s (0.4 in / s) in draft mode print quality Continuous mode: 40 mm / s (1.6 in / s) in full print quality; 1 mm / s (0.04 in / s) in draft print quality |

| Barcode printing | EAN 8, EAN 13, UPC-A, UPC-E, Code 39, EAN 128, Code 128, ITF and RSS (including 2D composite codes); other codes available on request | EAN 8, EAN 13, UPC-A, UPC-E, Code 39, EAN 128, Code 128, ITF and RSS (including 2D composite codes); other codes available on request |

| Estimated peak performance (single line code, continuous mode) | Up to 700 prints per minute | Up to 250 prints per minute |

| Operator interface | TFT SVGA 800 x 480 full color LCD touch screen, WYSIWYG print preview, built-in full diagnostics, 3 levels of password protection, wide range of languages | TFT SVGA 800 x 480 full color LCD touch screen, WYSIWYG print preview, built-in full diagnostics, 3 levels of password protection, wide range of languages |

| Master / follower capability (ability to control up to 4 encoders from one user interface) | Control of up to four DataFlex® 6530 encoders using a single CLARiTY control unit | Control of up to four DataFlex® 6530 encoders using a single CLARiTY control unit |

| Standard communication | RS232, dual Ethernet, USB memory stick and reader support, ASCII and binary communication protocols, Windows drivers, and ZPL and SATO emulations | RS232, dual Ethernet, USB memory stick and reader support, ASCII and binary communication protocols, Windows drivers, and ZPL and SATO emulations |

| Web browser capability s | Yes | Yes |

Coding Guarantee

- iAssure ™ technology automatically detects the most common printing defects, reducing waste and unwanted product rework, as well as the additional time required for labor to correct the error.

- CLARiTY ™ software helps ensure that the correct code is always printed on the correct product.

Advantage of longer operating time

- Intelligent Motion ™ technology eliminates the need for compressed air, as well as associated costs and downtime, helping to consistently maximize print quality and print head life.

- Discover code readability issues that indicate possible encoder maintenance needs.

- The industry-leading, easy-to-replace cassette is designed for faster tape replacement that maximizes uptime.

- The high capacity of the tape and the variety of saving modes of this maximize the time between changes.

Simple usability

- Its design allows it to withstand the toughest production line environments.

- Few parts wear out and they are easy to change, improving production line uptime.

- Thanks to the compact design, it adapts to practically any production line.

- It has a simple operator interface.

Integrated productivity

- Electronic print head control eliminates the need for compressed air.

- Code quality is automatically maintained and avoids the risk of operators over-modifying conventional power and air settings.

- Rapid print head change and few wear parts reduce production interruption time for replacements.

- The cassette is easy to load.

Applications

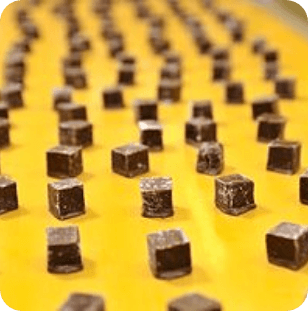

Candy and confectionery

Bakery products and cereals

Fruits and vegetables