Videojet 6210, Thermal Transfer Printer

The Videojet 6210 thermal transfer printer is a proven and cost-effective solution for users migrating to a digital solution from equipment with analog encoding technologies such as heat printing and roller coders. It is perfect for low speed continuous and intermittent motion flexible packaging applications, especially in the food industry.

| Specification | Value |

|---|---|

| Printer mode | Intermittent and continuous movement |

| Gap between prints | 1mm (0.039 ”) |

| Tape length | 700 meters (766 yards) |

| Belt widths | 22mm (0.87 ”) and 33mm (1.3”) |

| Continuous mode: | |

| Maximum printing area (width x length) | 32 x 40 mm (1.26 x 1.57 ”) |

| Printing speed | 500 mm / s (19.69 inch / s) |

| Minimum print speed | 40mm / s (1.57 inch / s) |

| Intermittent mode: | |

| Maximum printing area (width x length) | 32 x 34 mm (1.26 "x 1.34") |

| Printing speed | 200mm / s (7.87 inch / s) |

| Minimum print speed | 50mm / s (1.96 inch / s) |

| Barcode printing | Only as logo |

| Estimated peak performance (single line code, continuous mode) | About 125 packs / min |

| Standard User Interface | 5.7 ”CLARiTY ™ Color SVGA LCD Touchscreen |

| Standard communication | RS232 and USB memory stick |

Provides consistent, high-quality printing and flexible coding:

- 300 dpi print resolution ensures high quality codes.

- Includes the patented belt motor, which allows you to fully control the movement and tension of the belt.

- Real-time variable data enables a variety of applications.

- Enables the printing of codes up to 32 mm (1.26 inches) wide at speeds of up to 125 packs / min

The simple use of the machines allows operators to focus on production and not the printer:

- The 5.7-inch CLARiTY ™ color touchscreen makes setup quick, easy and with fewer errors.

- Variable date and time fields are automatically updated, eliminating the time and effort often spent modifying stamps

- The tape cassette ensures that replacement is quick and easy, compared to having to insert the tape into the encoder.

The uptime advantage reduces downtime, saving production time and money:

- Ribbon tension is maintained evenly by a reliable error-free motor that eliminates ribbon-related downtime.

- Continuous and intermittent printing on the same machine encompasses future packaging equipment upgrades.

- Ribbon length of 700 meters (766 yards) and print gap of 1mm (0.039 inches) means ribbon is changed less frequently than printing systems.

- Interleaving, an innovative ribbon-saving feature, can double your ribbon utilization, saving money and reducing the frequency of ribbon changes.

The Coding Guarantee helps avoid coding errors that can lead to high costs:

- Advanced coding software virtually eliminates code setting errors.

- CLARiSOFT ™ code design software prevents dates from being wrongly printed, codes missing, and job rework, with associated production cost.

Applications

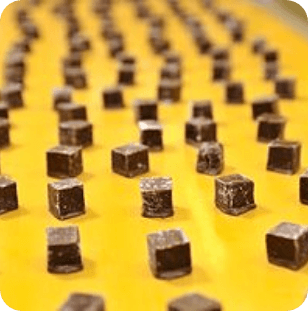

Candy and confectionery

Bakery products and cereals

Fruits and vegetables

Dairy products