Videojet 2120

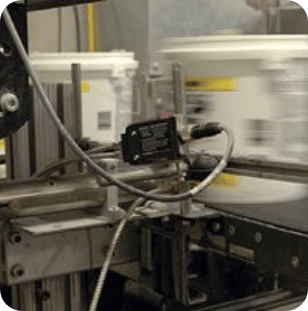

The Videojet 2120 is an easy-to-use printer that allows one or two line alphanumeric codes to be applied to a range of products or packages. A selection of print heads and inks allow you to print on a wide range of porous and non-porous materials. The Model 2120 works with two print heads to apply the code to two sides of the case and offers various printer controls from one screen for the most complex and multi-line codings.

| Specification | Value |

|---|---|

| 700 series print head | |

| Substrate | Porous |

| Number of points | 7 or 16 |

| Print height | 13mm to 50mm (0.5 ”to 2”) |

| M Maximum print speed (based on number of dots) |

72 m / min (236 ft / min) or 113 m / min (371 ft / min) |

| 800 series print head | |

| Substrate | Not porous |

| Number of points | 7 or 16 |

| Print height | 11mm to 92mm (0.4 "to 3.6") |

| Maximum print speed (based on number of dots) |

87 m / min (285 ft / min) or 126 m / min (413 ft / min) |

| Minimum print speed | 8 m / min (26 ft / min) |

| Ink capacity | 1 L, 5 gallon (18.9 L) optional |

| Standard User Interface | CLARiTY® 5.7 ”Color SVGA LCD Touchscreen |

| Master / follower functionality (Ability to control up to 4 printers from one user interface) |

Up to 4 |

| Standard communication | RS232, Ethernet and USB memory stick |

| Web browser functionality | Yes |

Application coverage on difficult surfaces:

- Inks are manufactured from quality materials so codes last on a range of products and surfaces.

- The compact design of the print heads allows easy integration into existing transport systems.

- Advanced print head tilt control technology allows print heads to be angled so that the height, density and style of the message match the design of the box.

The integrated color touch screen makes operator intervention easy:

- The on-screen editor allows you to create and edit messages instantly.

- On-screen gauges display data on ink usage, job status, counts, message preview, and other production-related information in one central location to monitor and interact with the printer.

- Access and control can be restricted with passwords to help ensure that no obstacles arise in your production.

The simple use of the machines allows operators to focus on production and not the printer:

- Integrated setup wizard reduces system setup time by offering operator guidance throughout the installation process.

- The printer can be operated in standalone mode via an intuitive interface or be connected to factory management systems or PLCs for centralized control.

- Communication protocols include Ethernet, RS232, and USB to suit your operating requirements.

- Print data can be encoded as text communication or ZPL.

- Can connect printer and packaging drivers for separate machine web browser functionality.

- Master / follower functionality lets you control up to four printers from one controller for more efficient job management.

Seamless integration with other Videojet products enables matching codes to be validated throughout the factory:

- Message selection is done from a single point and can be transferred to multiple devices.

- CLARiNET® software connects all Ethernet devices, including scanners and scales, in the production area.

Applications

Drinks

Construction materials

Fruits and vegetables

Dairy products